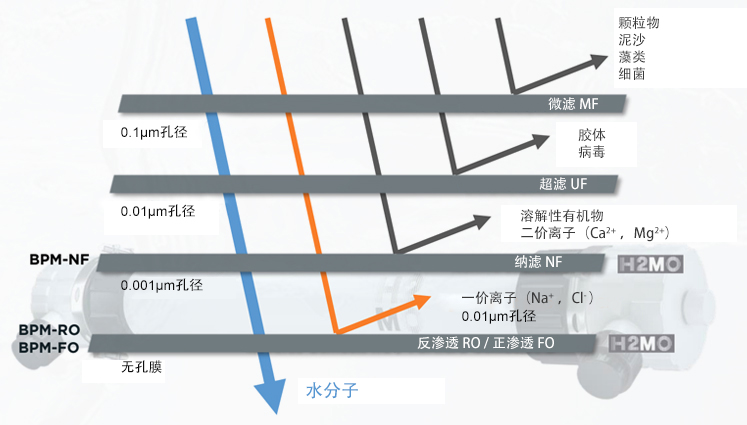

BPM 水分离膜由独特的生物材料配方制成,能够生产具有增强透水性、选择性截留和高通量的膜。

使用不同的生物材料配方,H2MO 可以制造反渗透膜、 纳滤膜、正渗透膜及其他专用膜。

为了制作高效的BPM膜,我们首先需要制作高性能的中空纤维膜丝。使用多种新型聚合物材料调配好的铸膜液和芯液经由喷丝头同时压出,经过空气浴后,铸膜液浸入凝固浴中形成膜丝。高耐压,高通量,高截留性能的中空纤维膜丝为BPM膜的制作提供了坚实的基础。

通过界面聚合和逐层自我组装,引入生物分子来控制薄膜的形成。这种生物分子可以调节薄膜的纳米结构,因此薄膜可以提供更多的水分子通道,从而大大增加了薄膜的通量。

通过调整模拟细胞膜功能的仿生材料的配方,H2MO 团队开发了一系列基于 BPM 技术的膜产品,这些产品具有不同的功能特性和应用场景。